2511, Burlington Tower, Business Bay,

PO Box No. 114193, Dubai, UAE

2511, Burlington Tower,

Business Bay, PO Box No. 114193,

Dubai, United Arab Emirates

2511, Burlington Tower, Business Bay,

PO Box No. 114193, Dubai, UAE

2511, Burlington Tower,

Business Bay, PO Box No. 114193,

Dubai, United Arab Emirates

Stainless steel fabrication is a remarkable process that combines craftsmanship with advanced techniques to create exceptional products. From architectural structures to industrial components, stainless steel has become a material of choice due to its durability, corrosion resistance, and aesthetic appeal.

With one of the largest and most technologically advanced manufacturing facilities in Asia, SMA Stainless does the key stainless steel fabrication techniques, including laser cutting, waterjet cutting, V-grooving, bending, and perforation, and delves into how these methods contribute to the production of precision-engineered stainless steel works.

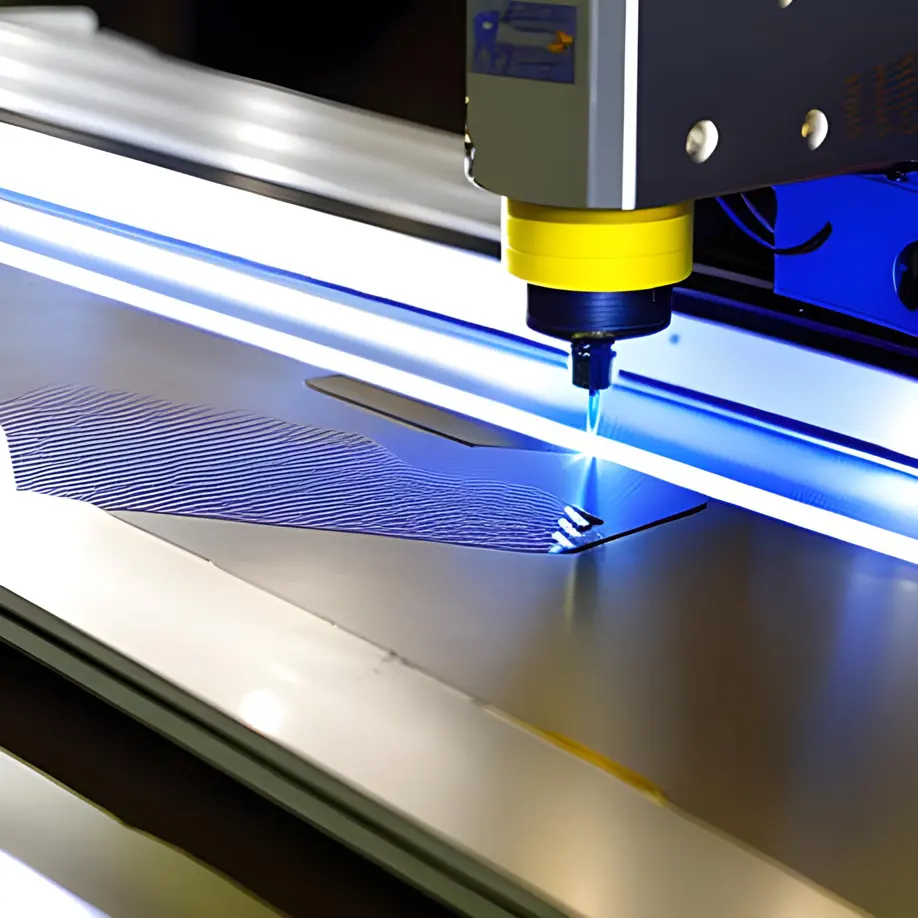

Laser cutting has revolutionized the field of stainless steel fabrication with its remarkable precision, speed, and versatility. SMA Stainless uses this technique that employs a high-powered laser beam to cut through stainless steel sheets with exceptional accuracy. Laser cutting offers numerous advantages, including minimal material wastage, clean edges, and the ability to handle a wide range of thicknesses. Its ability to create complex shapes and intricate designs makes it an invaluable tool in the fabrication of stainless steel works.

Waterjet cutting is another prominent method used in stainless steel fabrication. SMA Stainless uses this technique that employs a high-pressure stream of water mixed with abrasive particles to precisely cut through stainless steel. Waterjet cutting offers a cold-cutting process, ensuring no heat-affected zones or thermal distortions. It is particularly advantageous for handling thicker stainless steel sheets and materials sensitive to heat. With its ability to produce intricate designs, sharp corners, and smooth edges, waterjet cutting is a valuable asset in the creation of high-quality stainless steel works.

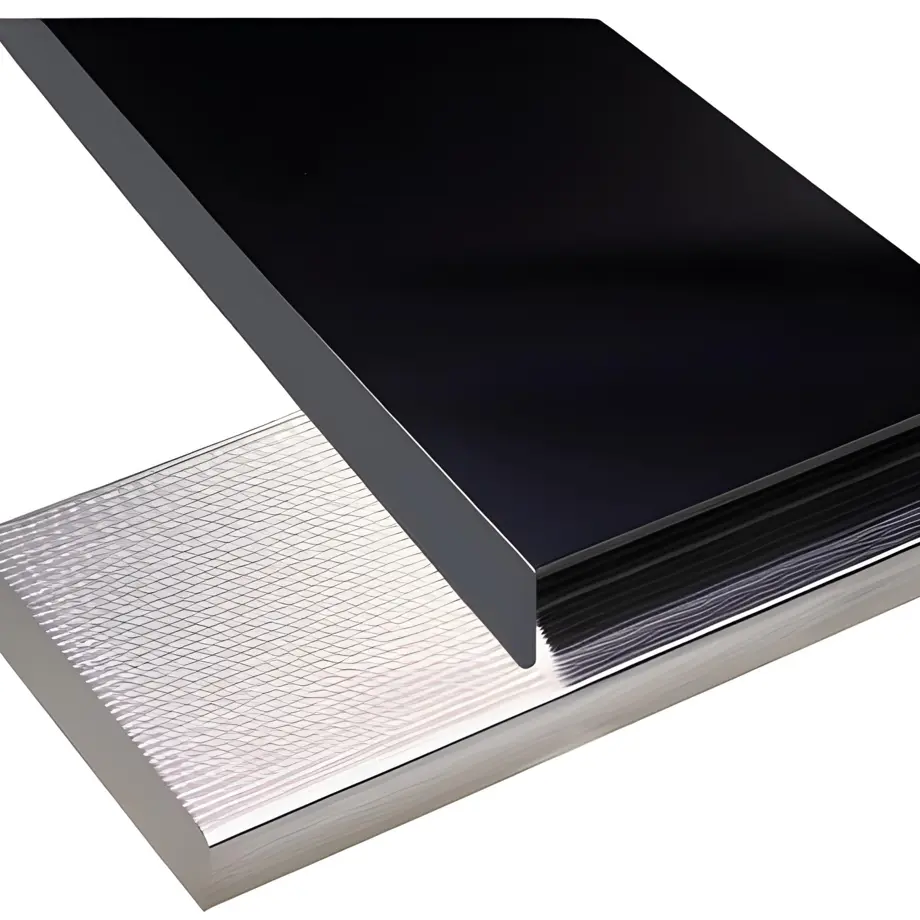

V-grooving is a technique that involves cutting a "V" / “90 degree bend” shape into stainless steel sheets, enabling precise folding and bending. SMA Stainless uses this process and is commonly employed to create complex geometries such as channels, corners, and edges that require accurate bending. V-grooving enhances the structural integrity of stainless steel works by providing clean and consistent grooves that facilitate precise folding and shaping.

Bending is an essential step in stainless steel fabrication as it converts flat sheets into three-dimensional structures. Stainless steel's excellent ductility allows for easy bending into various shapes and angles. Press braking and roll bending are two commonly used techniques by us. Precision bending ensures that stainless steel works achieve the desired form, whether it be a simple curve or a complex architectural structure.

Perforation adds both functionality and visual appeal to stainless steel works. SMA Stainless uses this process that involves creating holes or patterns in stainless steel sheets. Stainless steel perforated sheets find applications in architecture, interior design, filtration systems, and more. Advanced methods such as CNC punching, laser perforation, and waterjet perforation offer precise hole patterns and geometries, allowing for customization and design flexibility.

Stainless steel fabrication techniques, including laser cutting, waterjet cutting, V-grooving, bending, and perforation, have elevated the art of creating stainless steel works to new heights. The precision, versatility, and aesthetic possibilities offered by these methods allow for the production of exceptional stainless steel products. From intricate designs and clean edges achieved through laser cutting and waterjet cutting to the structural integrity and customization made possible by V-grooving, bending, and perforation, stainless steel fabrication techniques play a vital role in transforming flat sheets of stainless steel into remarkable three-dimensional creations. As the field of stainless steel fabrication continues to evolve, these techniques will continue to push the boundaries of what is possible, enabling the creation of innovative and visually stunning stainless steel works. From architectural marvels to functional components, stainless steel fabrication stands as a testament to the fusion of craftsmanship and technological advancements, delivering enduring quality and design excellence.